COLUMN (C-7):-

Assume column size = 10″ x 15″ = 150 sq. inch

a) Load Calculation:-

Load from F. B – A2,A3 = = 15.19 kip

Load from F. B – A3,A4 = = 8.25 kip

Load from F. B – A3,D3 = = 15.95 kip

Self weight of Column = x 150 x (10 – ) = 1.40 k

Factored load = 1.2 x 1.40 + 15.19 + 8.25 + 15.95

= 41.07 kip

Total column load for 6 – stored = 6 x 41.07 = 246.42 kip

b) Check for size:-

Pu = 243.11 (kip) (story -1) / ρg = 0.02

Pu = Ag [ .85f′c (1- ρg) + ρgfy]

Or, 246.42 = 0.80 x 0.65 x Ag [0.85 x 3 (1- 0.02) + .02 x 40]

Ag = 143.64 inch

Size of column = 10″ x 15″

Provided size = 150 in

c) Calculation of steel:-

Pu = [0.85 x f′c (Ag – Ast) + Ast fy]

Or, 150 = .80 x .65 x [.85 x 3 x (150- Ast) + Ast x 40]

Ast = 2.27 in

Use # 7 bars, Ap = 2.40 in

Tie bar:-

Use # 3 bar @ as Tie

S = 16 x Main bar dia = 16 x = 14″ c / c

S = 48 x Tie bar dia = 48 x = 18″ c / c

S = Minimum width of column = 10″ c /c

We use # 3 bar @ 10″ c / c

COLUMN (C-8):-

Assume column size = 10″ x 24″

a) Load Calculation:-

Load from F. B – B2,B3 = = 24.08 kip

Load from F. B – B3,B4 = = 13.08 kip

Load from F. B – B3,C3 = = 8.11 kip

Load from F. B – D3,B3 = = 3.12 kip

Self weight of Column = x 150 x (10 – ) = 2.25 k

Factored load = 24.08 + 13.08 + 8.11 + 1.2 x 2.25+20 k

= 67.97 kip

Total column load for 6 – story = 67.97 x 6 = 407.82 kip

b) Check for size:-

Pu = 407.82 (kip)

Pu = Ag [ .85f’c (1- ρg) + ρgfy]

Or, 407.82 = 0.80 x 0.65 x Ag [0.85 x 3 (1- .02) + .02 x 40]

Ag = 237.80 in

Size of column = 10″ x 24″

Provided size = 240 in

So, Ok

c) Calculation of steel:-

Pu = [0.85 f′c (Ag – Ast) + Ast fy]

Or, 407.82 = .80 x .65 x [.85 x 3 x (240- Ast) + Ast x 40]

Ast = 4.59 in

Use 8 # 7 bars st, Ap = 4.80 in

Tie bar:

Use # 3 bar as Tie

S = 16 x = 10″ c / c

S = 48 x = 18″ c / c

S = Minimum width of column = 10″ c / c

We use # 3 bar @ 10″ c / c

COLUMN (C-9):-

Assume column size = 10″ x 15″ = 150 sq. inch

a) Load Calculation:

Load from F. B – B3, C3 = = 7.81 kip

Load from F. B – C2, C3 = = 6.81 kip

Load from F. B – C3, C4 = = 3.06 kip

Load from stair Beam = = 19.38 kip

Self weight of Column = x 150 x (10 – )/1000 = 1.97 k

Factored load = 1.2 x 1.97 + 7.81 + 3.06 + 19.38 +20

= 59.42 kip

Total column load for 6. story = 6 x 59.42= 356.54 kip

b) Check for size:-

Pu = 116.232 kip

Pu = Ag [ .85f′c (1- ρg) + ρgfy]

Or, 356.54 = 0.80 x .65 x Ag [0.85 x 3 (1- .02) + .02 x 40]

Ag = 207.83 in

Size of column = 10″ x 21″

Provide, Ag = 10″ x 21″= 210 in

So, ok.

c) Calculation of steel:-

Pu = [0.85 f′c (Ag – Ast) + Ast fy]

Or, 356.54 = .80 x .65 x [.85 x 3 x (210- Ast) + Ast x 40]

Ast = 4.00 in

Use 10 # 6 bar straight.

Tie bar:-

Use # 3 bar as Tie

S = 16 x = 12″ c / c

S = 48 x = 18″ c / c

S = Minimum width of column = 10″ c / c

We use # 3 bar @ 10″ c / c

Check for lateral tie:-

S = = 4.75″ < 6″

So, Ok

No latered ties are required.

COLUMN (C-10):-

Assume column size = 10″ x 15″ = 150 sq. inch

a) Load Calculation:-

Load from F. B – A3, D3 = = 15.95 kip

Load from F. B – D3, D4 = = 9.29 kip

Load from F. B – D3, B3 = = 13.08 kip

Self weight of Column = 150 x x 9′ = 1.41 k

Factored load = 15.95 + 9.29 + 13.08 + 1.41 x1.2

= 40.00 kip

Total column load for 6- story = 6 x 40 = 240 kip

b) Check for size:-

Pu = 240 kip (Story -1)

Pu = Ag [ .85 x f′c (1- ρg) + ρg fy]

Or, 240 = .80 x .65 x Ag [.85 x 3 (1- 0.02) + .02 x 40]

Ag = 139.90 in

Size of column = 10″ x 14″

Provided size = 10″ x 15″= 150 Sq. inch.

Ok.

c) Calculation of steel:-

Pu = [0.85 f′c (Ag – Ast) + Ast fy]

Or, 240 = .80 x 0.65 [.85 x 3 (150- Ast) + Ast x 40]

Ast = 2.11 in

Use 4 # 7 bar st, Ap = 2.40in

Tie bar:

Use # 3 bar as Tie

S = 16 x = 14″ c / c

S = 48 x = 18″ c / c

S = Minimum width of column = 10″ c / c

We use # 3 bar @ 10″ c / c

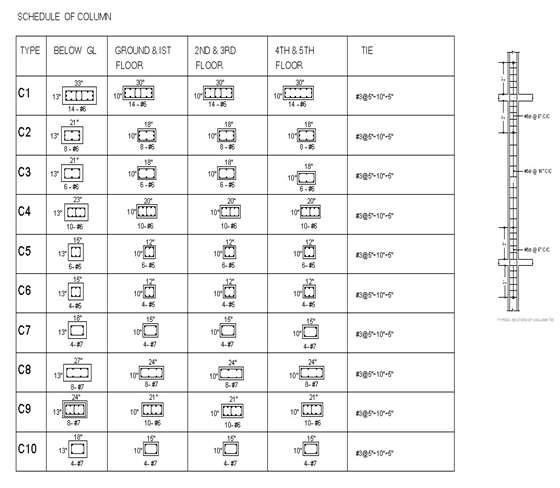

Table:- 4.4. Details of sectional dimensions and reinforcement arrangement of all Columns (C – 1 ~ C – 10):

| Columngroup | Numberof Column | ColumnSize | Columnload | Area of steel req. (sq.inch) | QuantityOf bars | Tie barsspacing |

| Pu (kip) | Ast | Main bars | Use # 3 bars | |||

|

C – 1 |

02 |

10″ X 30″ |

516.34 |

6.10 |

14 # 6 |

10″ C/c |

|

C – 2 |

02 |

10″ X 18″ |

308.96 |

3.60 |

8 # 6 |

10″ C/c |

|

C – 3 |

02 |

10″ X 18″ |

289.77 |

2.52 |

6 # 6 |

10″ C/c |

|

C – 4 |

02 |

10″ X 20″ |

342 |

3.95 |

10 # 6 |

10″ C/c |

|

C – 5 |

02 |

10″ X 12″ |

189 |

1.53 |

6 # 5 |

10″ C/c |

|

C – 6 |

02 |

10″ X 12″ |

152.5 |

0.34 |

4 # 5 |

10″ C/c |

|

C – 7 |

02 |

10″ X 15″ |

246.42 |

2.27 |

4 # 7 |

10″ C/c |

|

C – 8 |

02 |

10″ X 24″ |

407.82 |

4.59 |

8 # 7 |

10″ C/c |

|

C – 9 |

02 |

10″ X 21″ |

356.54 |

4.00 |

10 # 6 |

10″ C/c |

|

C- 10 |

02 |

10″ X 15″ |

240.00 |

2.11 |

4 # 7 |

10″ C/c |

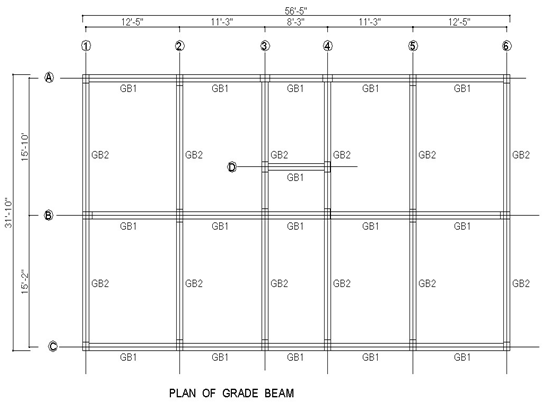

Figure Plan of Grade beam

Design of grade beams:

Design Data:–

Materials:-

Fy = 40 ksi

f′c = 3 ksi

wc = 150 pcf

w brick = 120 pcf

Thickness of wall on GB = 5″

Clear cover = 3″

Grade Beam GB-1:

Size = 10″ x 15″

Effective depth (d) = 15-3 = 12 inch

a) Load Calculation:-

Self weight of beam GB-1 = x 150 = 156.25 Ib/ft

All main wall weight = ( 10- )x120 = 430.00 Ib/ft

Total Dead load = 156.25 + 450 = 606.25 Ib/ft

Factored load GB-1 = 1.2 DL = 1.2 x 606.25

= 727.5 Ib/ft

= 0.73 k/ft

b) Moment Calculation and ‘d’ check:-

(-) Ve moment at Ext. support = = 7.04 k-ft

(+) Ve moment at Mid span = = 8.04 k-ft

(-) Ve moment at Int. support = = 11.26 k-ft

Mu = 11.26 k-ft

b = 0.85ß1 x x

= 0.85 x 0.85 x x

= 0.037

max = 0.75 b = 0.75 x 0.037 = 0.028

Mu = bd fy (1-0.59 x

Or 11.26 x 12 = 0.9 x 0.028×12 x d x 40 x (1-0.59 x .028 x

= 3.78″ < 12″

So, ok

c) Reinforcement Calculation:

Mid span steel:-

= = 62.03 < 200 psi

min = = = 0.005

min = = = 0.0041

As = bd = 0.005x 12 x 12 = 0.72 inch

Use 2 # 6 hanger bar.

Steel for Int. Support:-

= = 86.88 psi < 200 psi

min = 0.005

min = 0.0041

As = bd = 0.005x 12 x 12 = 0.72 inch

Use 2 # 6 hanger bar.

Steel for Ext. Support:-

= = 54.32 psi < 200 psi

As = bd = 0.005x 12 x 12 = 0.72 inch

Use 2 # 6 hanger bar.

d) Stirrup design:-

Vv = 1.15 x = 4.86 K

Vu = 4.86 – ( ) x.73 = 4.13 k

Vc = 2 bw d = 2 x 10 x 12 = 13.14 k

Shear strength of concrete,

Vc = .75 x 13.14 = 9.86 K

Since, Vc > Vd; no shear reinforcement is required.

Use # 3 bar @ = = 6″ c / c throughout beam length.

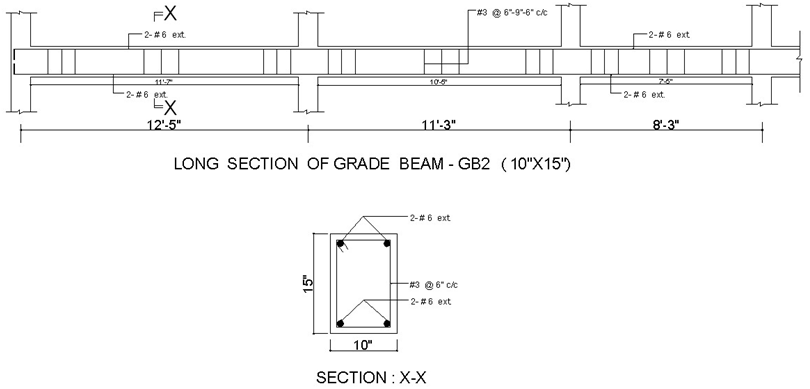

Grade Beam GB-2:

Size = 12″ x 15″

Effective depth, (d) = 15-3 = 12 inch

a) Load Calculation:-

Self weight of beam GB-2 = x 150 = 156.25 Ib/ft

All main wall weight = ( 10- ) x120 = 450.00 Ib/ft

Total Dead load = 156.25 + 450.00 = 606.25 Ib/ft

Factored load GB-2 = 1.2 DL = 1.2 x 606.25

= 727.5 Ib/ft

= 0.73 k/ft

b) Moment Calculation and d check:-

(-) Ve moment at Ext. support = = 11.43 k-ft

(+) Ve moment at Mid span = = 13.07k/ft

(-) Ve moment at Int. support = = 18.79 k-ft

Now, Mu = 18.79 k-ft

b = .85x 1 x x

= 0.85 x 0.85 x x

= 0.037

max = 0.75 x 0.037 = 0.028

Mu = bd fy (1-0.59 x

Or 18.79 x 12 = 0.9 x .028×12 x d x 40 x (1-0.59 x .028 x

= 4.88″ < 12″

So, ok

c) Reinforcement Calculation:

Mid span steel:-

= = 100.84 < 200 psi

min = = = 0.005

min = = = 0.0041

As = bd = .005x 12 x 12 = 0.72

Use 2 # 6 bar hanger

Steel for Int. Support:-

= = 144.98 psi < 200 psi

min = 0.005

As = 0.005x 12 x 12 = 0.72 inch

Use 2 # 6 bar hanger.

Steel for Ext. Support:-

= = 88.19 psi < 200 psi

min = 0.005

As = 0.005x 12 x 12 = 0.72 inch

Use 2 # 6 bar hanger .

d) Stirrup design:-

Vu = 1.15 x = 6.29 K

Vu = 6.29 – ( ) x .73 = 5.57 k

Vc = 2 bw d = 2 x 10 x 12 = 13.14 k

Shear strength of concrete,

Vc = 0.75 x 13.14 = 9.86 K

Since, Vc > Vd; no shear reinforcement is required.

Use # 3 bar @ = = 6″ c / c throughout beam length.

v\:* {behavior:url(#default#VML);}

o\:* {behavior:url(#default#VML);}

w\:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

Normal

0

false

false

false

EN-US

X-NONE

X-NONE

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:”Table Normal”;

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-qformat:yes;

mso-style-parent:””;

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin:0in;

mso-para-margin-bottom:.0001pt;

mso-pagination:widow-orphan;

font-size:10.0pt;

font-family:”Calibri”,”sans-serif”;}

table.MsoTableGrid

{mso-style-name:”Table Grid”;

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-priority:59;

mso-style-unhide:no;

border:solid windowtext 1.0pt;

mso-border-alt:solid windowtext .5pt;

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-border-insideh:.5pt solid windowtext;

mso-border-insidev:.5pt solid windowtext;

mso-para-margin:0in;

mso-para-margin-bottom:.0001pt;

mso-pagination:widow-orphan;

font-size:10.0pt;

font-family:”Times New Roman”,”serif”;

mso-fareast-font-family:”Times New Roman”;}

Figure Reinfrocement Grade Beam ( GB-2 )

Table : Details of sectional dimensions and reinforcement arrangement of all grade beams ( GB- 1 GB – 2).

|

Grade Beam Group |

Grade Beam Size |

Moment (Kip-ft) |

Area of steel req. (Sq. inch) |

Quantity of bars |

Stirrups (Spacing” C/c) |

|||||

|

At Ext. M-Ve |

At Mid M + Ve |

At Int. M-Ve |

At Ext. As-Ve |

At mid As+Ve |

At Int. M-Ve |

Main bars |

Extra Top/bottom |

|||

|

GB – 1 |

10″ x 15″ |

7.04 |

8.04 |

11.26 |

0.72 |

0.72 |

0.72 |

At Ext, Suppt: 2 # 6 |

– |

@ 6″ C/c |

|

At Mid, Span: 2 # 6 |

– |

@ 6″ C/c |

||||||||

|

At Int, Suppt: 2 # 6 |

– |

@ 6″ C/c |

||||||||

|

GB – 2 |

10″ x 15″ |

11.43 |

13.07 |

18.79 |

0.72 |

0.72 |

0.72 |

At Ext, Suppt: 2 # 6 |

– |

@ 6″ C/c |

|

At Mid, Span: 2 # 6 |

– |

@ 6″ C/c |

||||||||

|

At Int, Suppt: 2 # 6 |

– |

@ 6″ C/c |

||||||||

Some are parts:

Analysis and Design of Building Components (Part 1)

Analysis and Design of Building Components (Part 2)

Analysis and Design of Building Components (Part 3)